Analyzes large-scale models quickly and accurately.

Nonlinear Static AnalysisPerforms calculations efficiently with superior convergence.

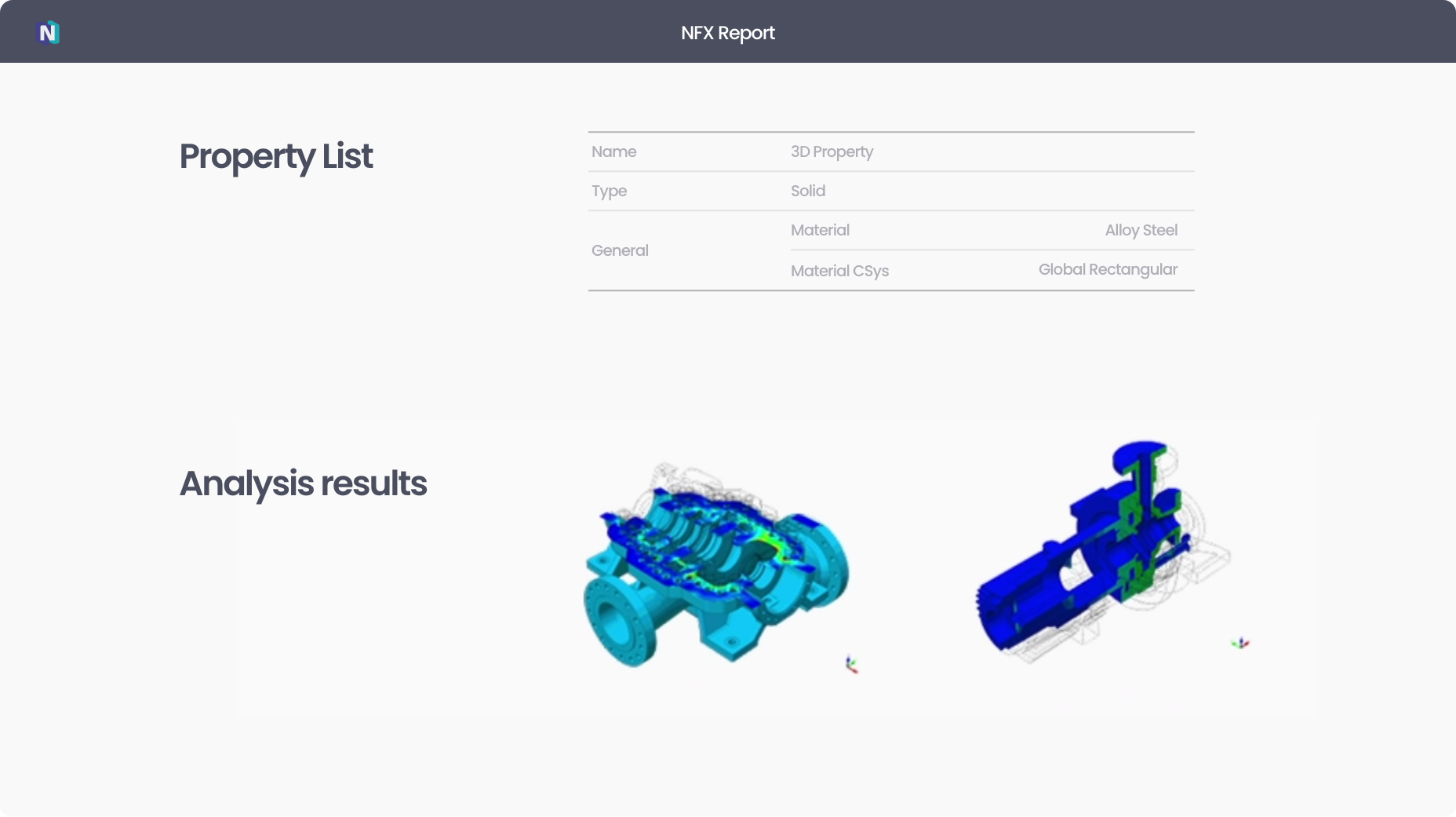

Linear Static Analysis of Medical Transport Equipment

Linear Static Analysis of Medical Transport Equipment

- Utilization of next-generation solvers: Multi-frontal solver and AMG solver

- High-speed analysis using a high-performance parallel solver

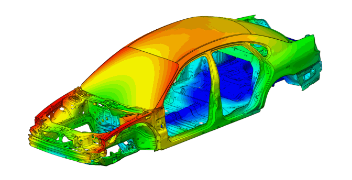

BIW Stiffness Evaluation

BIW Stiffness Evaluation

- Stiffness evaluation of the vehicle body BIW subjected to various loads.

- Fast analysis is possible even for models exceeding 1 million degrees of freedom (DOF).

Lens mount rail travel simulation

Lens mount rail travel simulation

- Linear contact analysis using sliding contact.

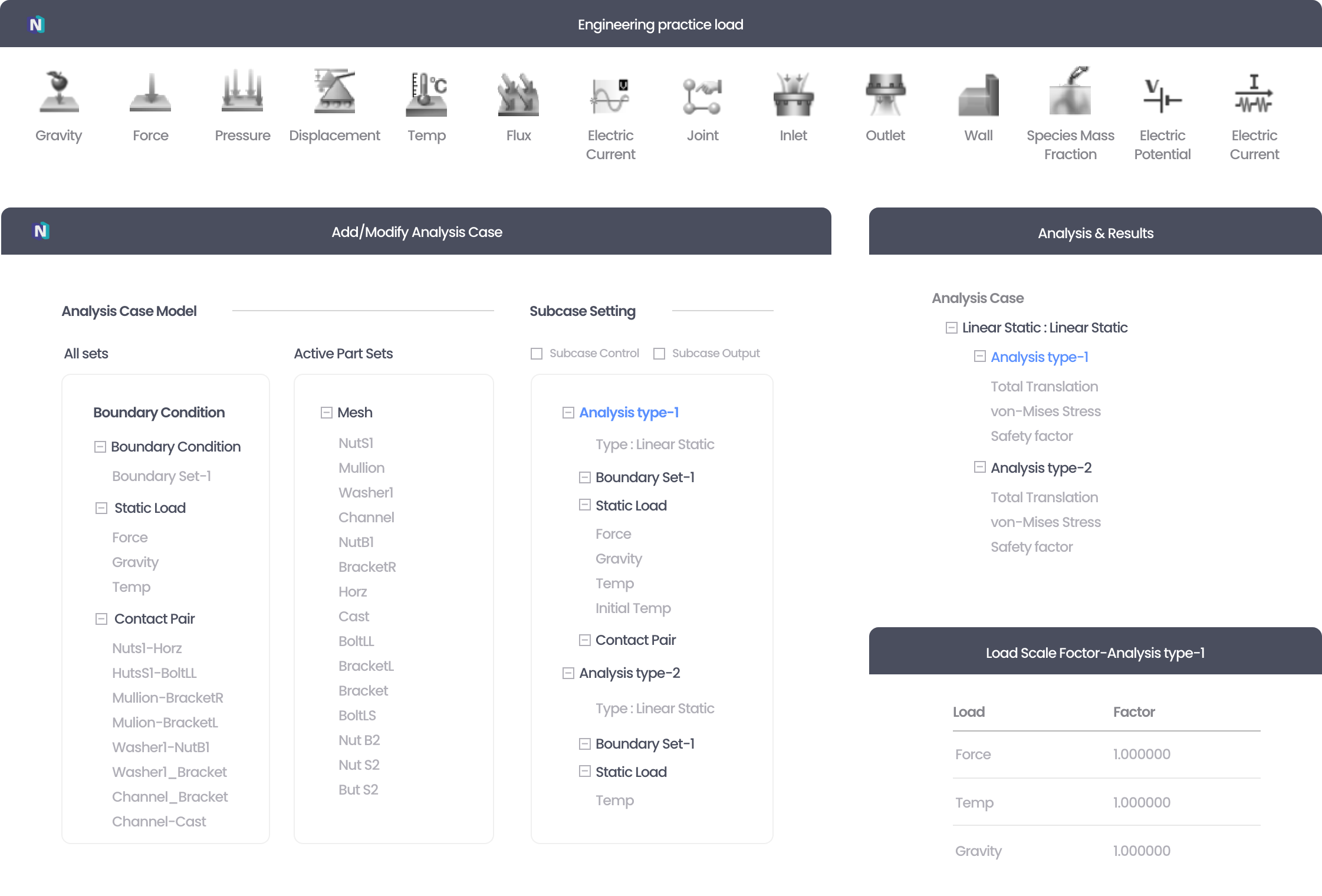

Transfer Equipment Simulation

Transfer Equipment Simulation

- Relative displacement analysis using sliding contact.

- Structural safety review through bolt stress analysis.

Weatherstrip material nonlinear analysis

Weatherstrip material nonlinear analysis

- Analysis of weatherstrip nonlinear behavior during automobile door opening/closing.

- Application of hyperelastic (rubber) model.

Seismic Performance Evaluation of a Seismic Damper

Seismic Performance Evaluation of a Seismic Damper

- Application of elasto-plastic material model using a Stress-Strain curve.

- Evaluation of energy absorption capacity during a seismic event.

Mobile phone connector insertion/removal analysis

Mobile phone connector insertion/removal analysis

- Nonlinear contact analysis considering friction.

- Residual stress analysis considering large deformation and material nonlinearity.

Boot seal nonlinear contact analysis

Boot seal nonlinear contact analysis

- Nonlinear analysis considering self-contact.

- Nonlinear analysis considering hyperelastic material / large deformation.

Eigenvalue Analysis of Semiconductor Equipment

Eigenvalue Analysis of Semiconductor Equipment

Automobile door transient response simulation

Automobile door transient response simulation

Seismic analysis applying Enforced Motion

Seismic analysis applying Enforced Motion

Analysis of dynamic characteristics of a marine refrigerator due to vibration load

Analysis of dynamic characteristics of a marine refrigerator due to vibration load

Seismic performance verification of an ultra-large extraction robot

Seismic performance verification of an ultra-large extraction robot

Brake System Thermal Capacity Evaluation

Brake System Thermal Capacity Evaluation

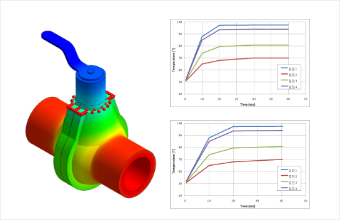

Transient heat transfer analysis of a ball valve using the sensor function

Transient heat transfer analysis of a ball valve using the sensor function

Brake System Thermal Capacity Evaluation

Brake System Thermal Capacity Evaluation

Instrument Panel Head Impact

Instrument Panel Head Impact

RCAR Rear Part Low Speed Impact

RCAR Rear Part Low Speed Impact

Hard disk drop analysis

Hard disk drop analysis

Sheet Metal Forming

Sheet Metal Forming

Fatigue Life Analysis of Vehicle Body

Fatigue Life Analysis of Vehicle Body

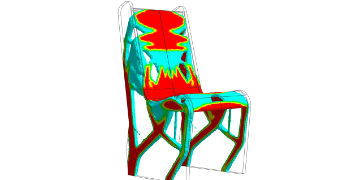

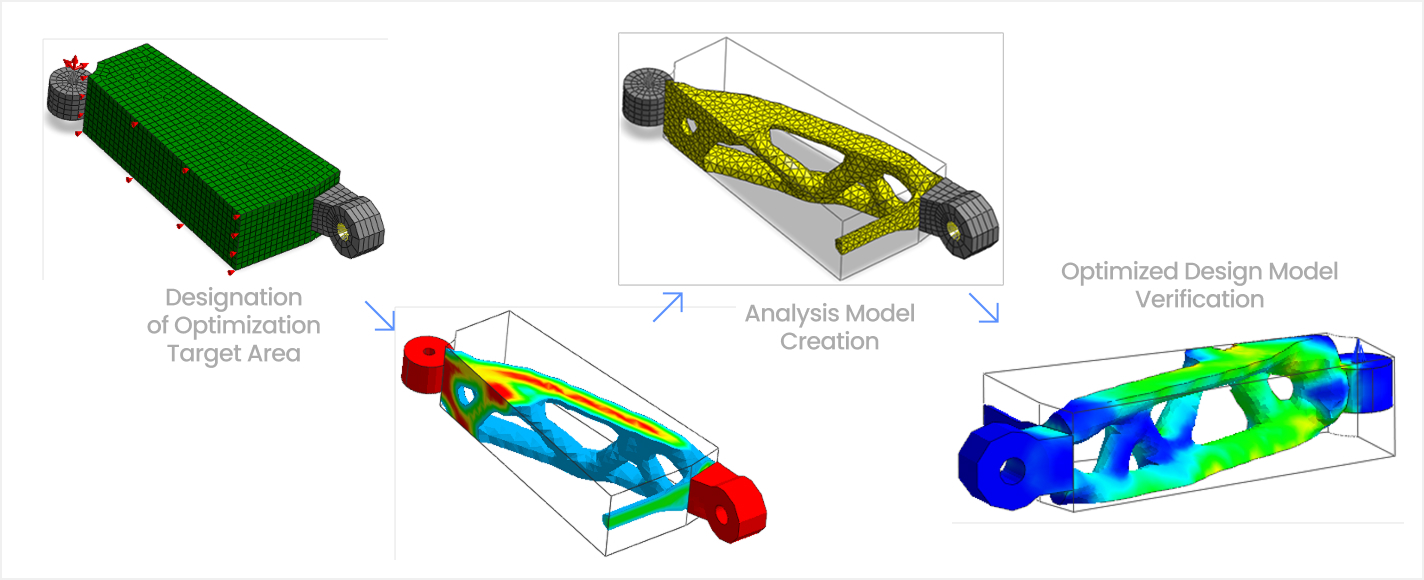

Topology Optimization Design Workflow

Topology Optimization Design Workflow

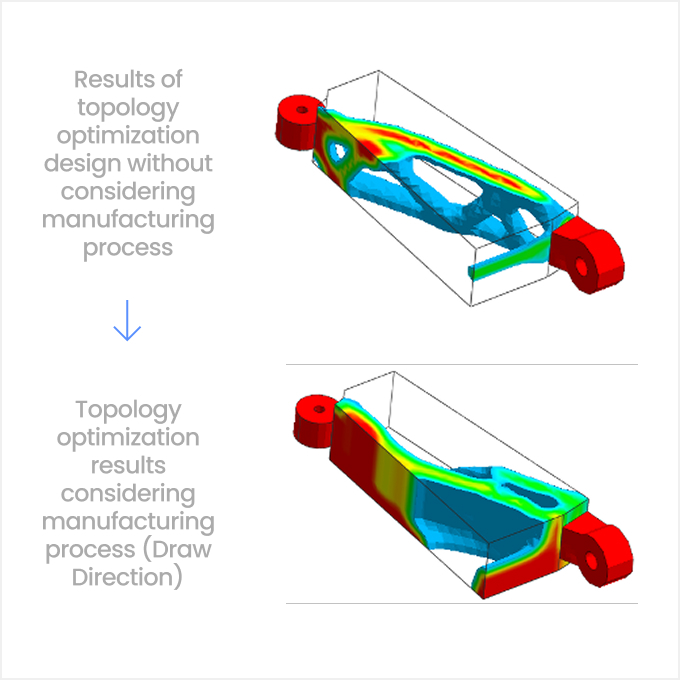

Topology Optimization Design Considering Manufacturing Processes

Topology Optimization Design Considering Manufacturing Processes

Topology Optimization Design Considering Constraints

Topology Optimization Design Considering Constraints

Stiffness Maximization Utilizing Linear Static Analysis

Stiffness Maximization Utilizing Linear Static Analysis

Volume Minimization Utilizing Frequency Response Analysis

Volume Minimization Utilizing Frequency Response Analysis

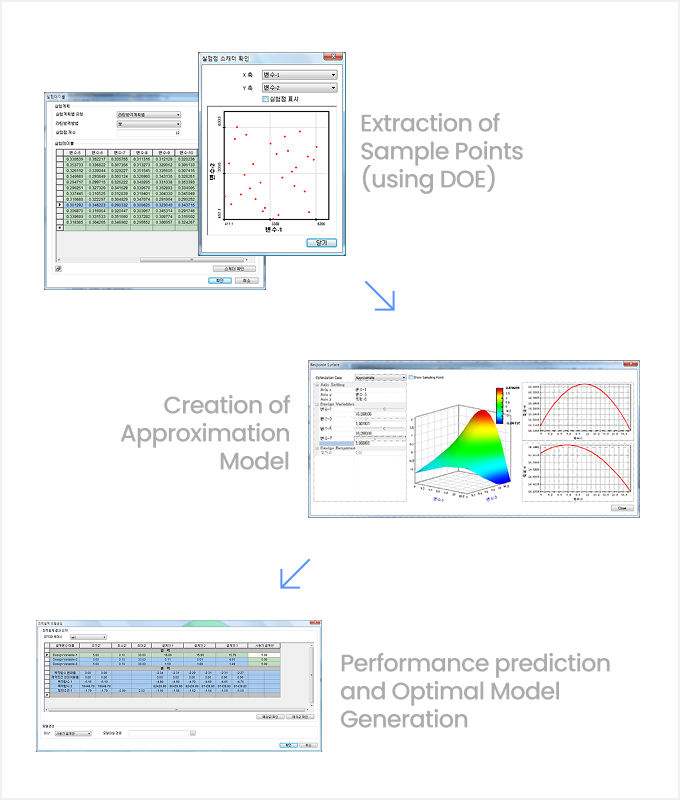

Workflow for Approximation Model-Based Size Optimization

Workflow for Approximation Model-Based Size Optimization

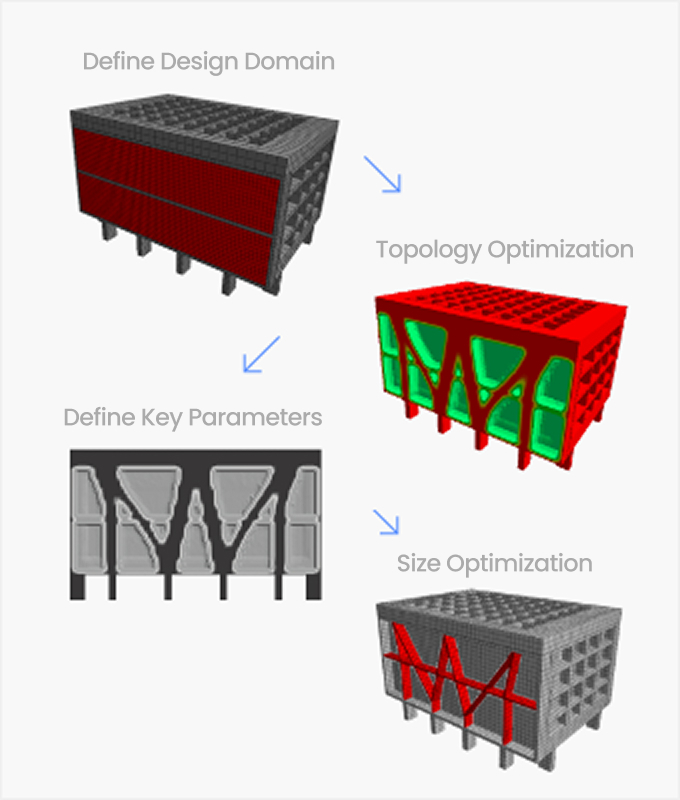

Workflow for Size Optimization Based on Topology Optimization Mode

Workflow for Size Optimization Based on Topology Optimization Mode

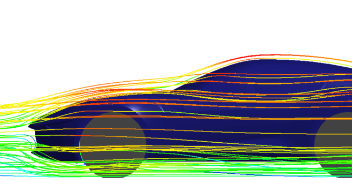

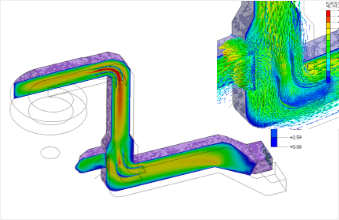

Flow Meter Fluid Flow Analysis and Structural Safety Evaluation

Flow Meter Fluid Flow Analysis and Structural Safety Evaluation

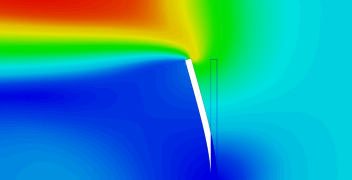

Thermal Power Plant Duct Guide Vane Design

Thermal Power Plant Duct Guide Vane Design

Wind Load Analysis of Membrane Structures

Wind Load Analysis of Membrane Structures

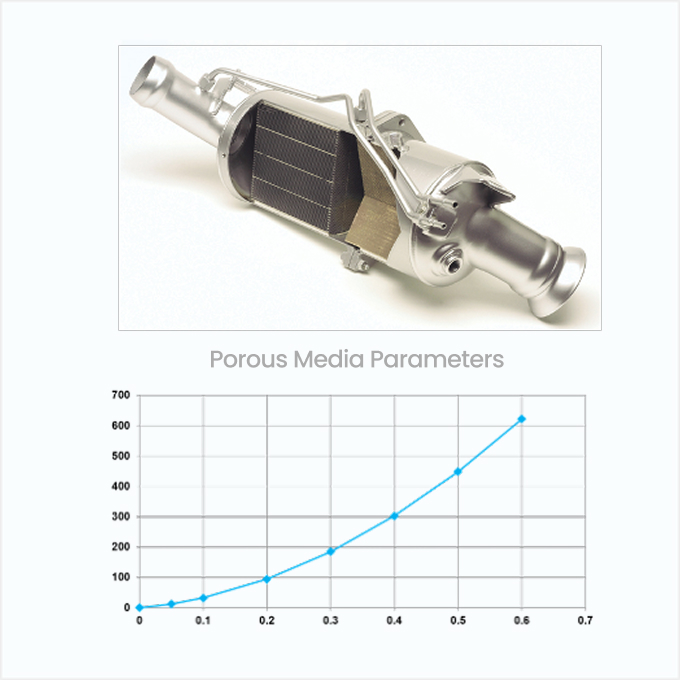

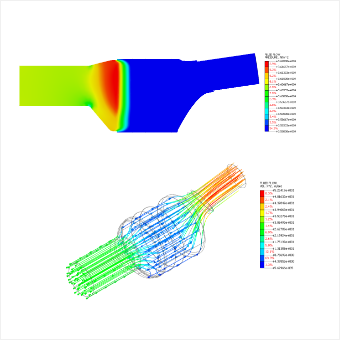

Catalytic Converter Analysis Utilizing the Porous Media Model

Catalytic Converter Analysis Utilizing the Porous Media Model

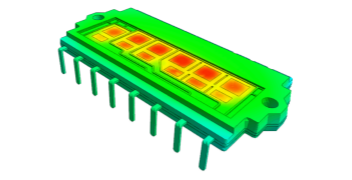

Heat Dissipation Performance Evaluation of LED Lighting

Heat Dissipation Performance Evaluation of LED Lighting

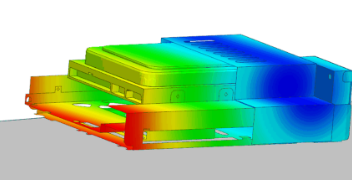

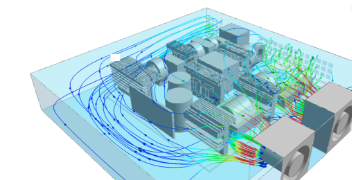

Graphics Card Cooling Performance Evaluation

Graphics Card Cooling Performance Evaluation

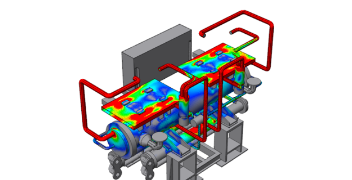

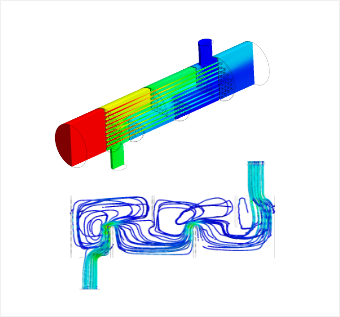

Thermo-fluid Analysis of Heat Exchanger

Thermo-fluid Analysis of Heat Exchanger

Coupled Thermo-fluid and Thermal Deformation Analysis of Heat Exchanger

Coupled Thermo-fluid and Thermal Deformation Analysis of Heat Exchanger

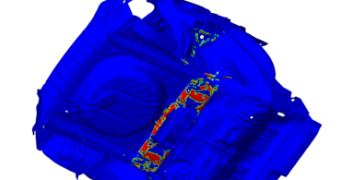

Thermo-fluid Analysis of Electrical Distribution Panel

Thermo-fluid Analysis of Electrical Distribution Panel

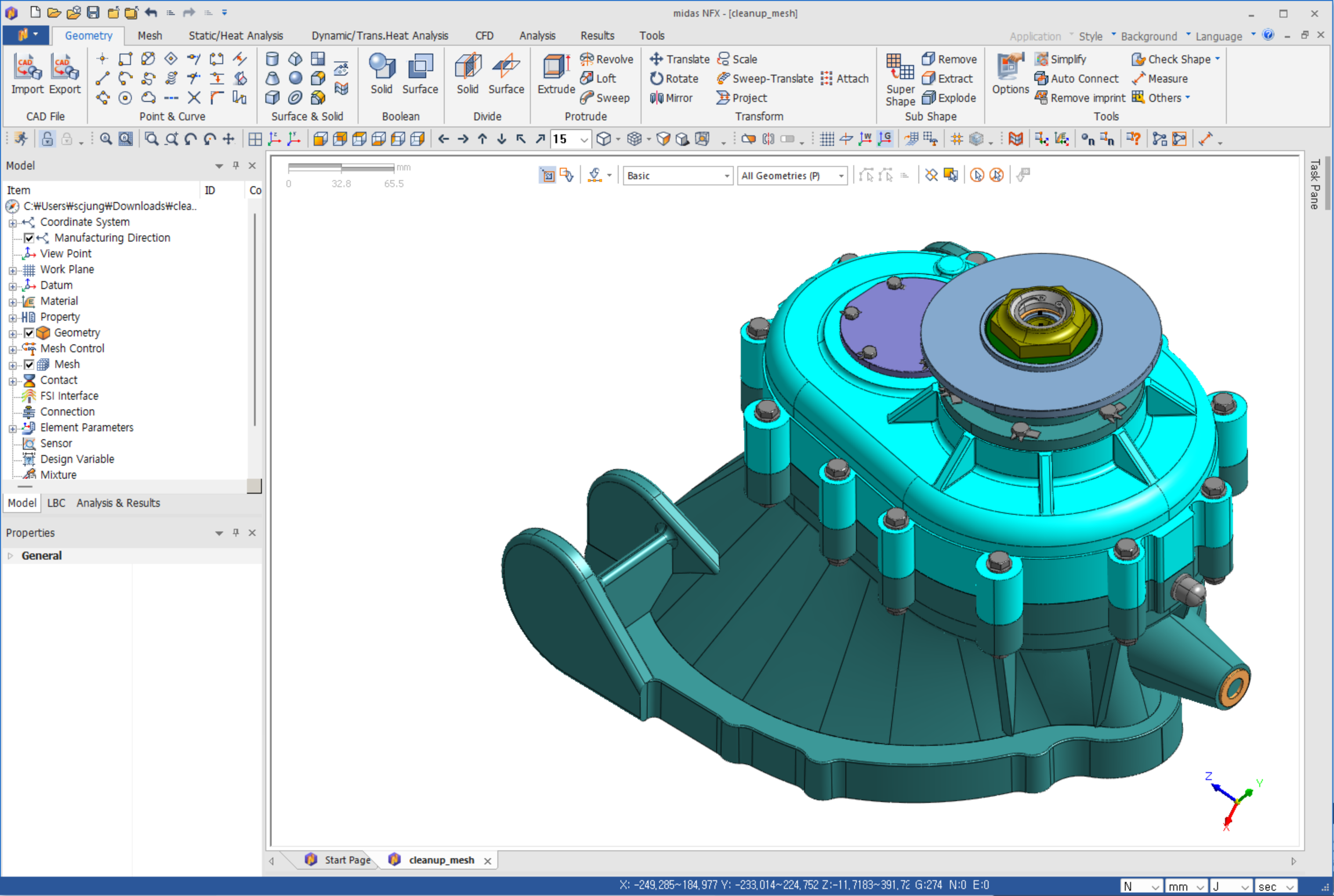

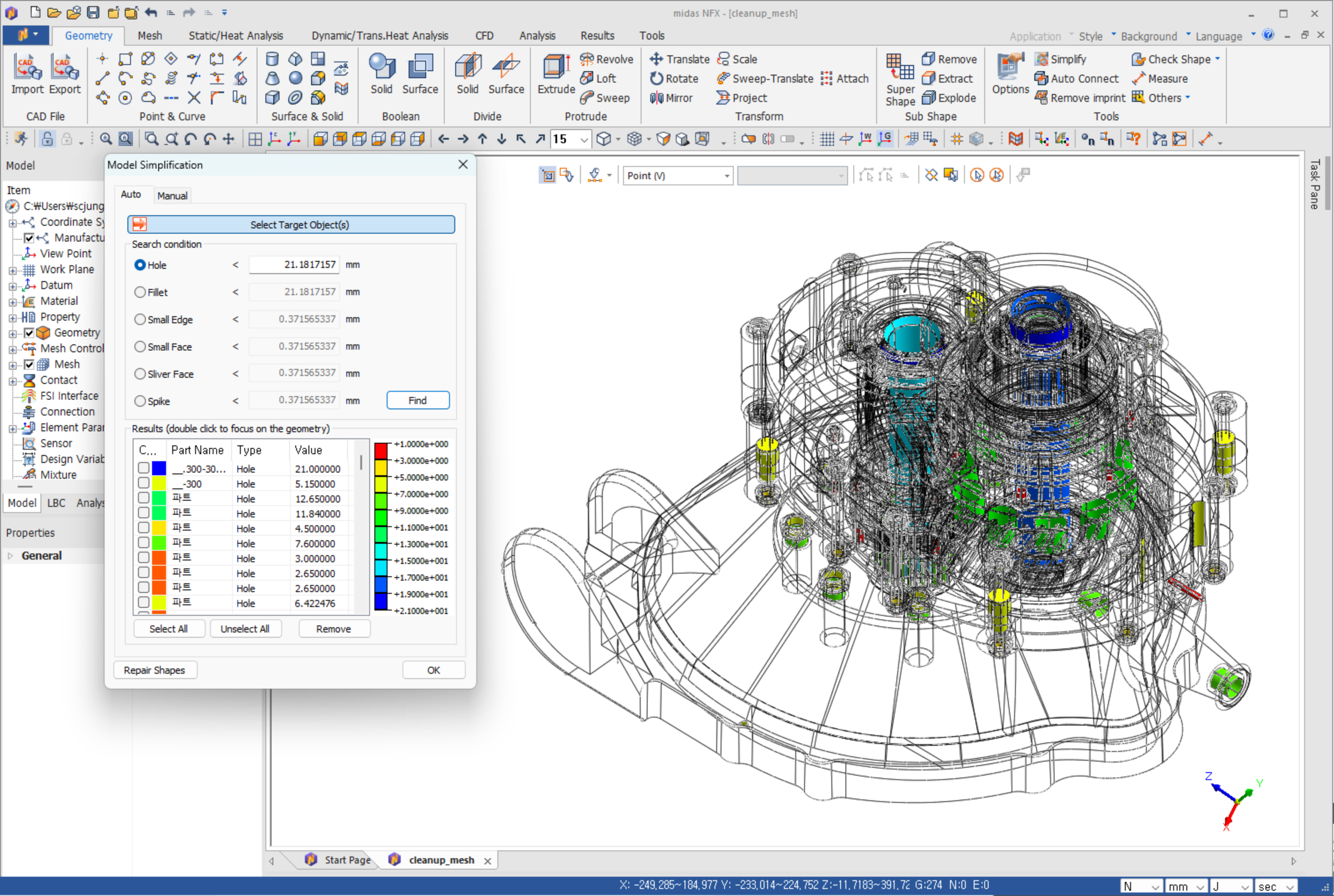

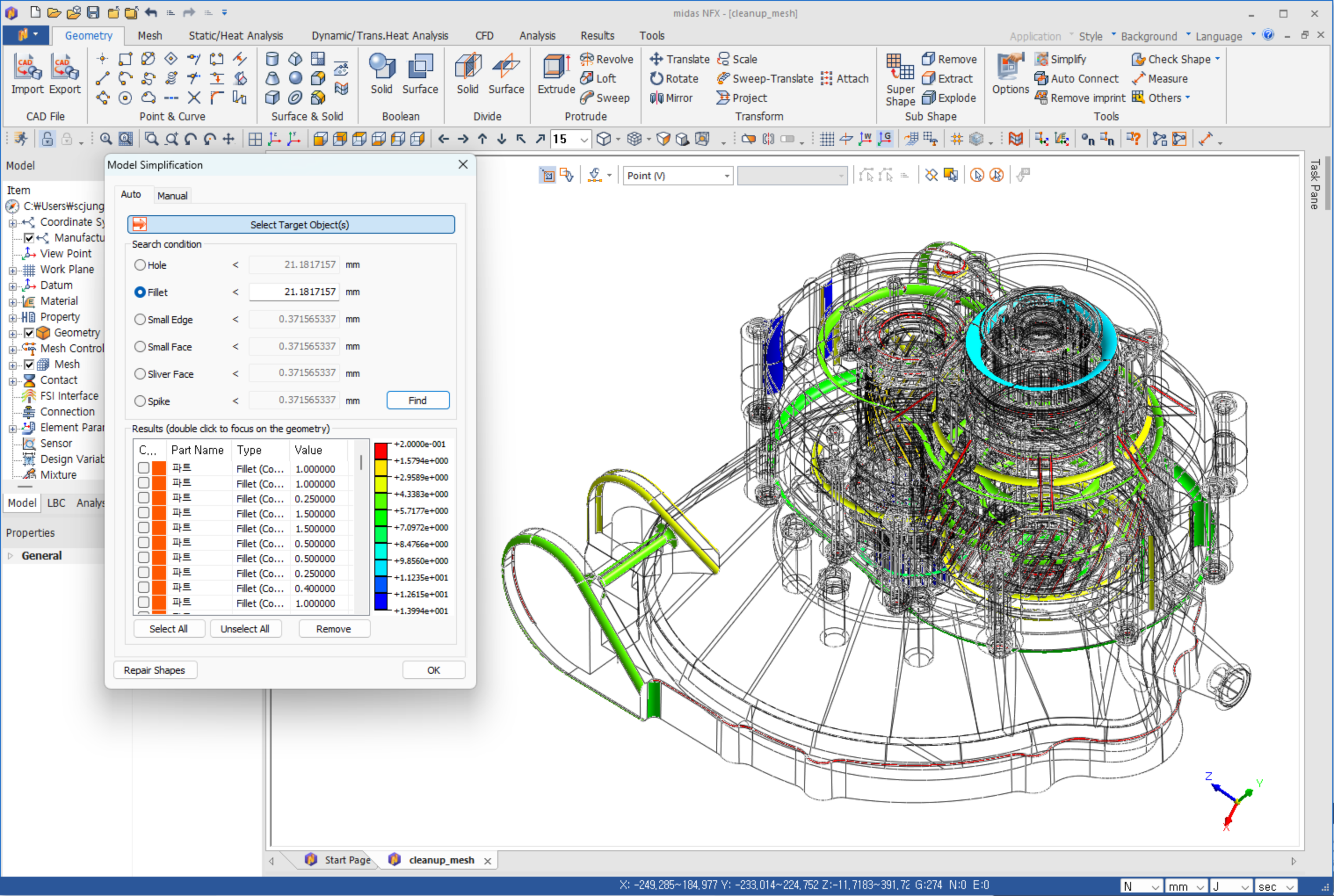

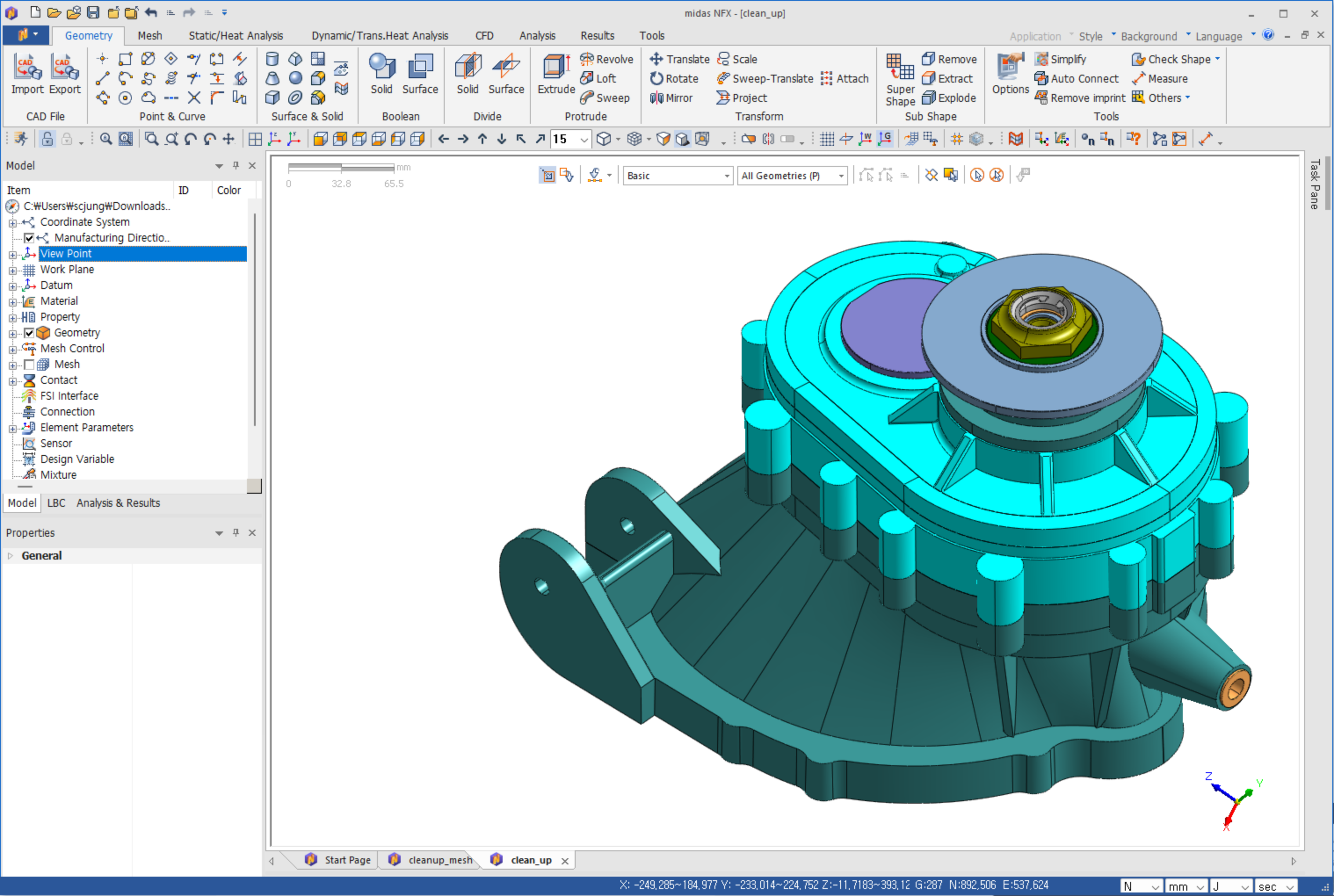

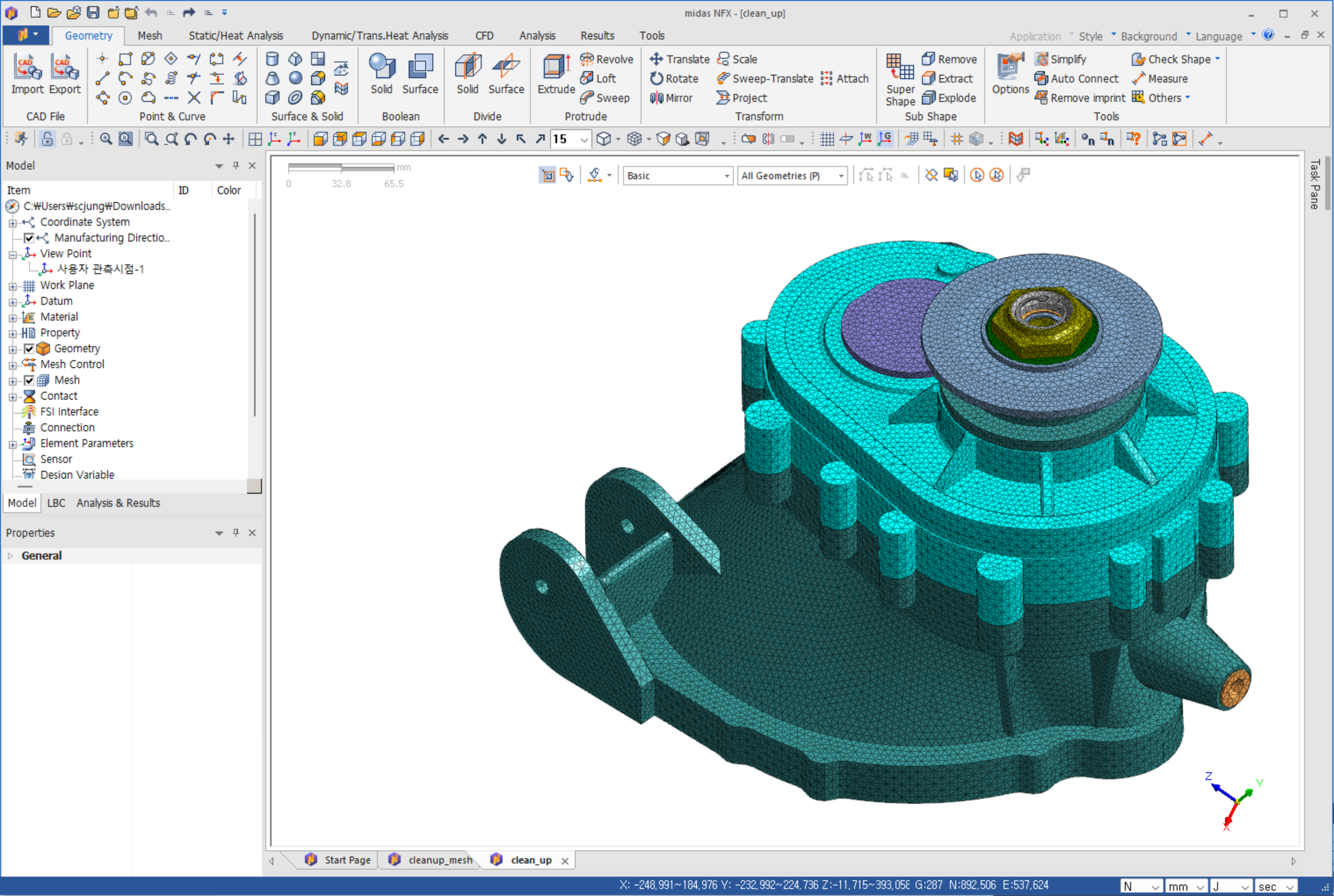

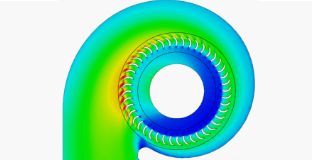

Flow Analysis of Boiler Blower

Flow Analysis of Boiler Blower

Blower Analysis Utilizing Mesh Deformation Module

Blower Analysis Utilizing Mesh Deformation Module

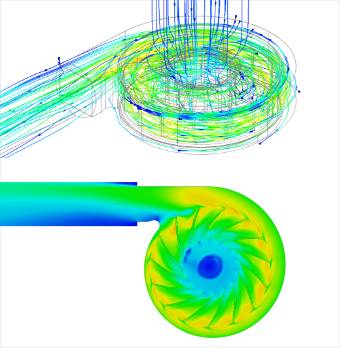

Centrifugal Fan Analysis Utilizing MRF Function

Centrifugal Fan Analysis Utilizing MRF Function

Agitator Analysis Utilizing MRF Function

Agitator Analysis Utilizing MRF Function

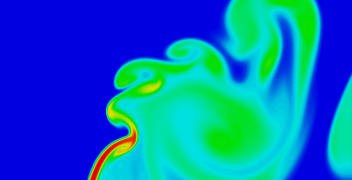

Mixing Performance Evaluation of Dual-Axis Agitator

Mixing Performance Evaluation of Dual-Axis Agitator

Gas Mixing Analysis Utilizing Mesh Deformation and Mixture Analysis

Gas Mixing Analysis Utilizing Mesh Deformation and Mixture Analysis

Pollutant Dispersion Assessment

Pollutant Dispersion Assessment

Analysis of Nitrogen Purging inside FOUP

Analysis of Nitrogen Purging inside FOUP

Air Purifier Performance Verification Analysis

Air Purifier Performance Verification Analysis

2-Way FSI Utilizing Deforming Mesh

2-Way FSI Utilizing Deforming Mesh

Vertical Axis Wind Turbine Flow Analysis

Vertical Axis Wind Turbine Flow Analysis

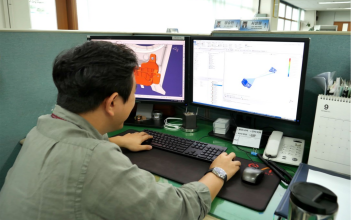

Clean Room Internal Flow Analysis

Clean Room Internal Flow Analysis

Wafer Surface Cleaning Analysis

Wafer Surface Cleaning Analysis

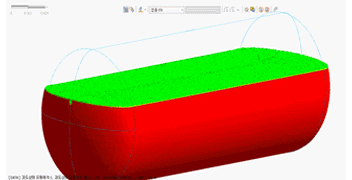

LNG Carrier Tank Sloshing Analysis

LNG Carrier Tank Sloshing Analysis

Oil Catch Can Flow Analysis

Oil Catch Can Flow Analysis