Suitable for models including complex NURBS Patches and Sliver Faces Provides rigid body and spring element features Linear contact support (Bonded / Bi-directional Sliding / General Contact) Support for various and practical load and boundary conditions Support for thermal deformation and thermal stress analysis due to temperature loads

Stiffness Evaluation of Major Automotive Parts

Stiffness Evaluation of Major Automotive Parts

- Applicable to models with complex NURBS Patches and Sliver Faces

- Perform stiffness evaluation using the original CAD model without a simplification process

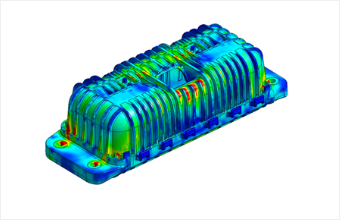

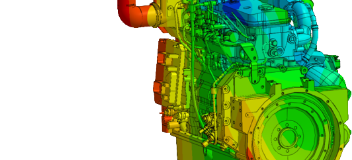

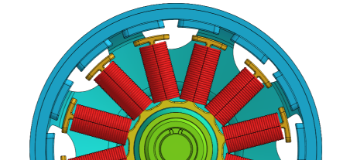

Engine Assembly Stiffness Evaluation

Engine Assembly Stiffness Evaluation

- Stiffness evaluation utilizing the CAD model without simplification and idealization processes

- Connecting numerous assembly components by applying linear contact conditions

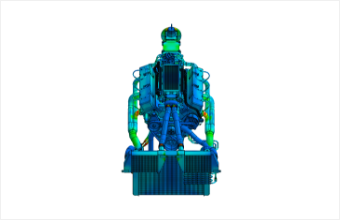

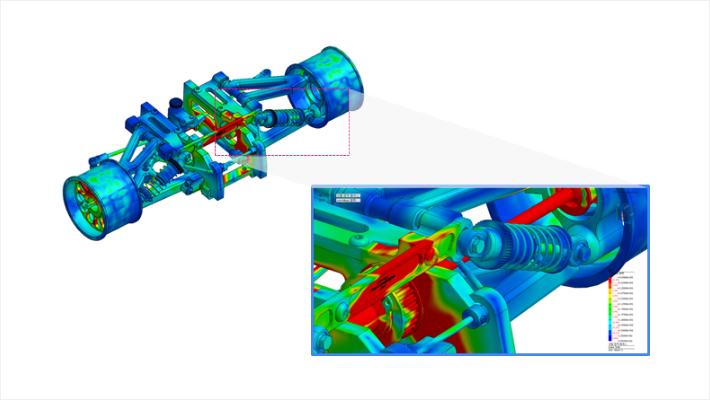

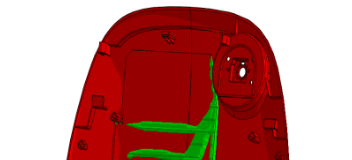

Structural Safety Analysis of Vehicle Suspension

Structural Safety Analysis of Vehicle Suspension

- Safety review through analysis of suspension displacement and stress under load application

- Analysis of maximum displacement and stress components occurring under vehicle load application

- Utilize the original CAE model directly without performing model simplification and idealization

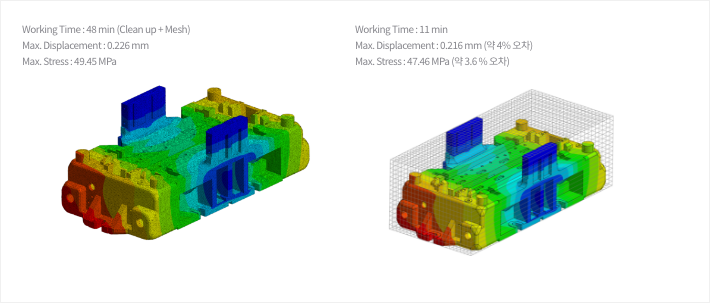

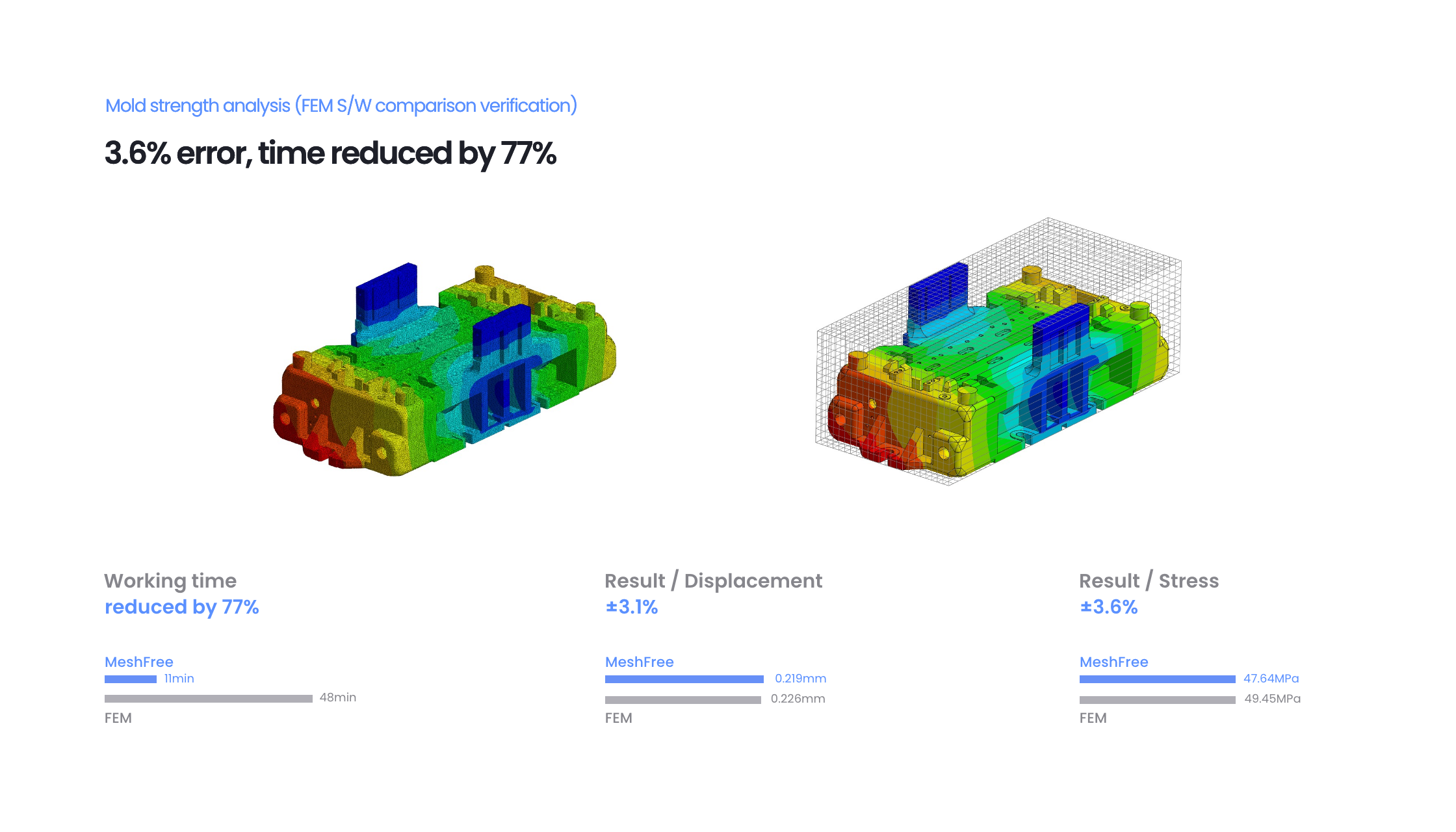

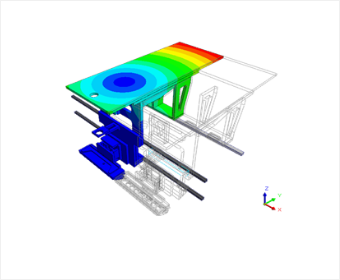

Mold Strength Analysis

Mold Strength Analysis

- Mold strength evaluation under self-weight and major vertical load application

- Verification of analysis time and results against FEM results

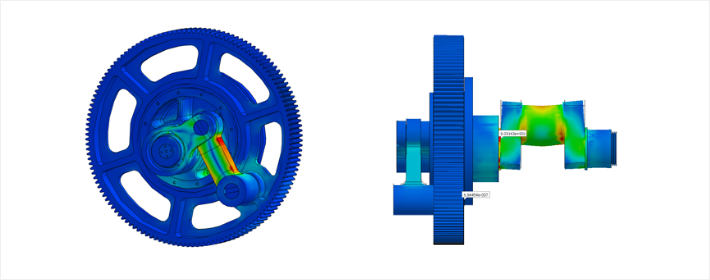

Gear Failure Cause Analysis

Gear Failure Cause Analysis

- Operating mechanism analysis and Load Path analysis to calculate operating loadsCheck for potential failure in bolt areas and link connection parts by applying general contact conditions

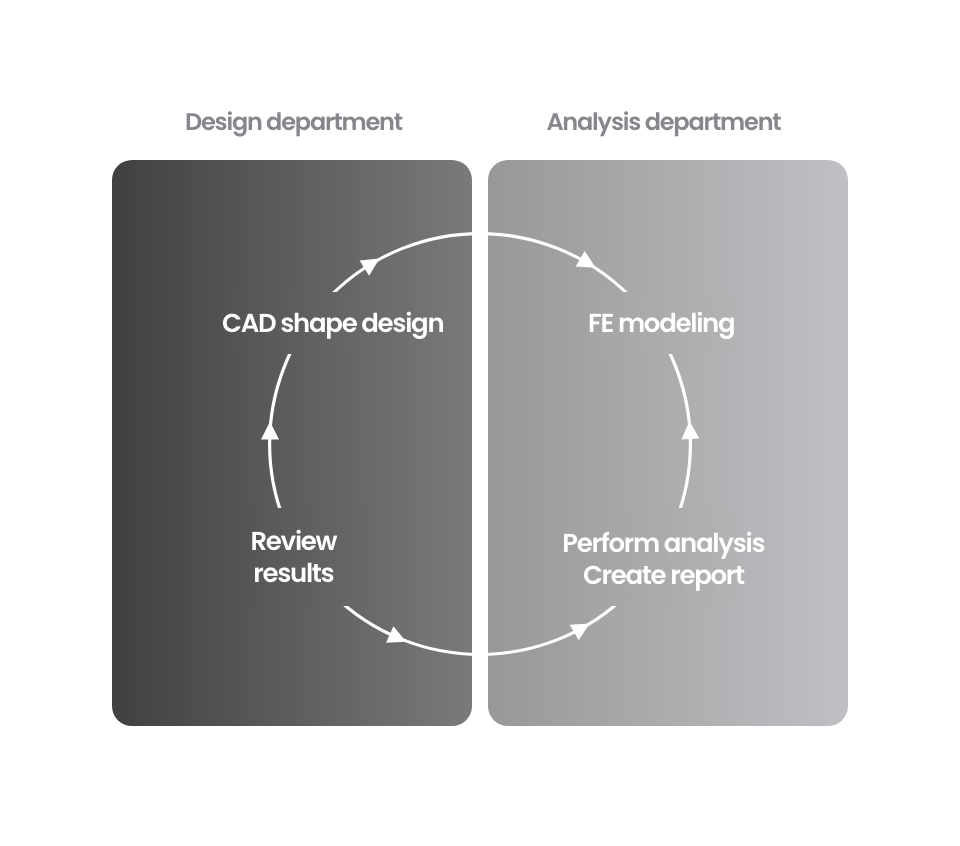

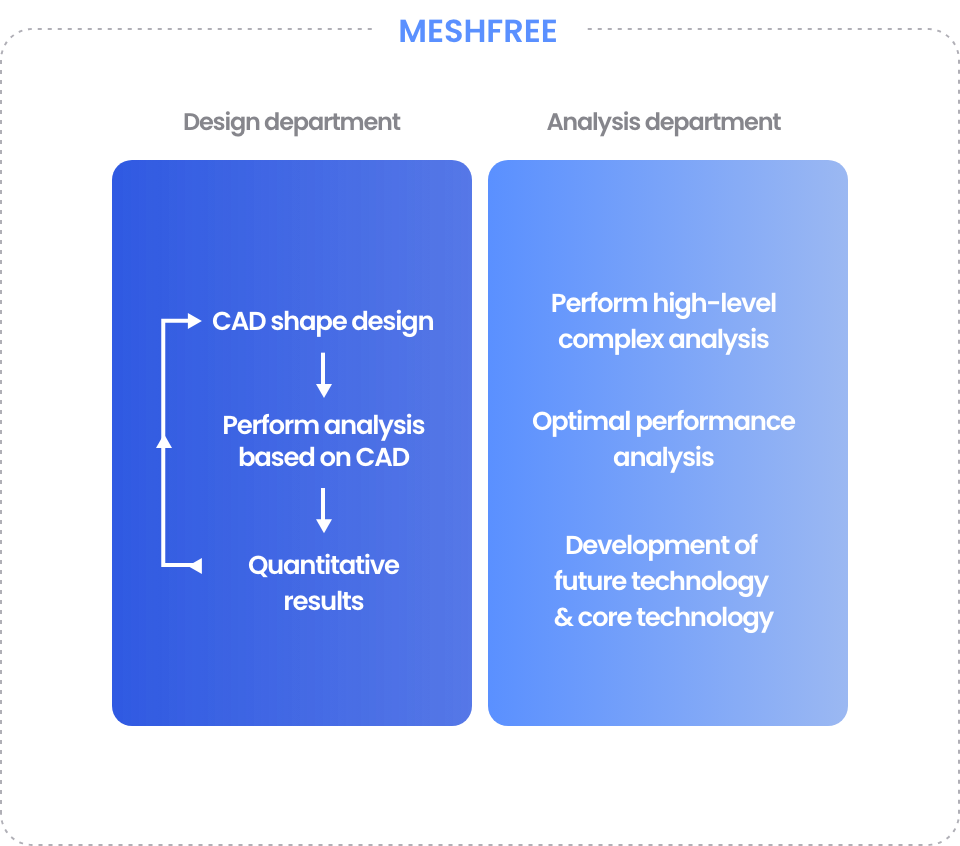

Design engineers

Design engineers

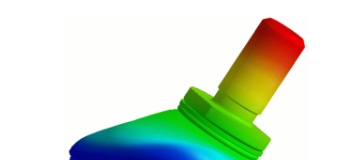

Medicine case in heat chamber

Medicine case in heat chamber

Analysis of plate spring strength and rigidity

Analysis of plate spring strength and rigidity

Backrest Strength Simulation Applying BIFMA Standards

Backrest Strength Simulation Applying BIFMA Standards

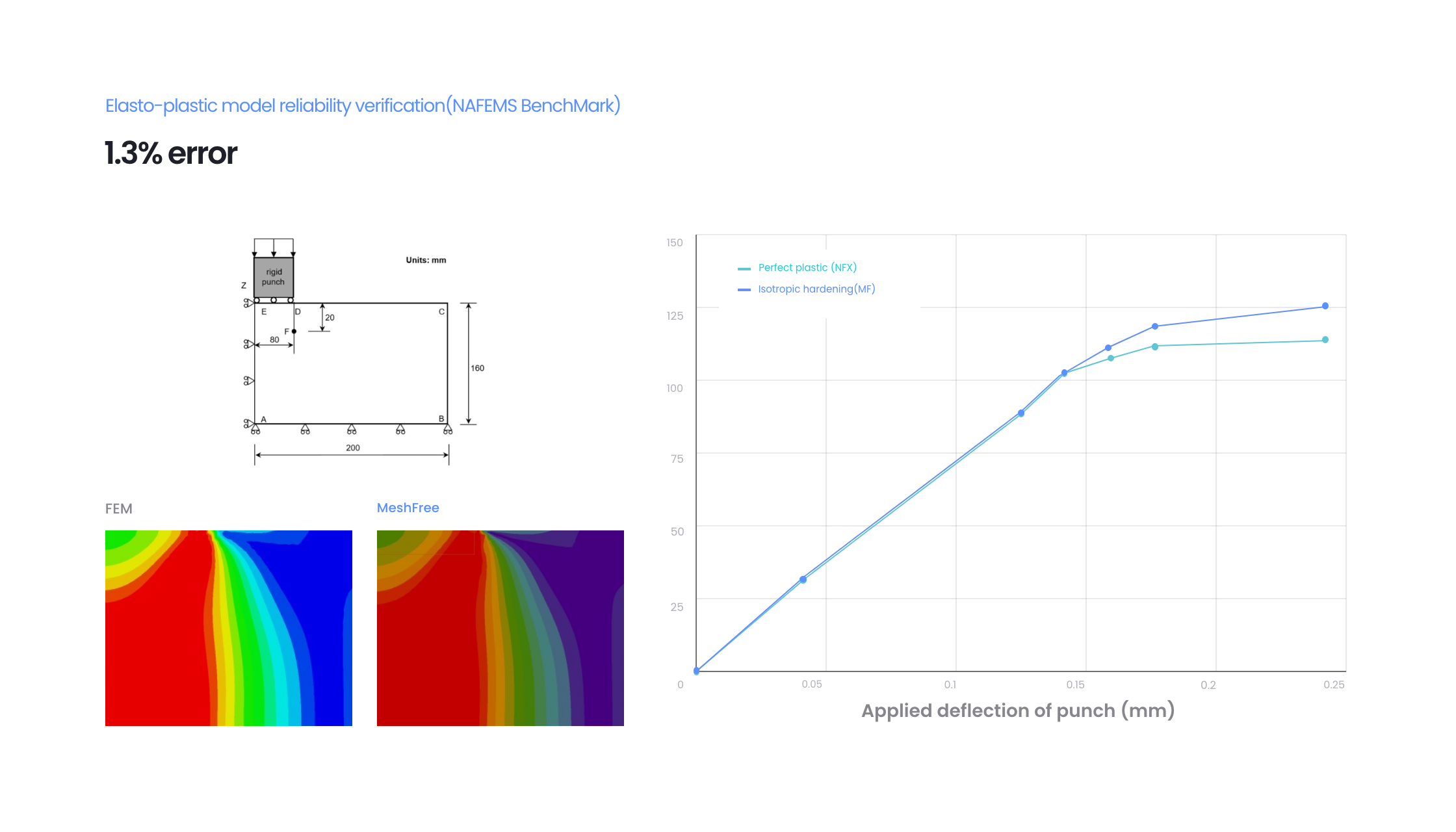

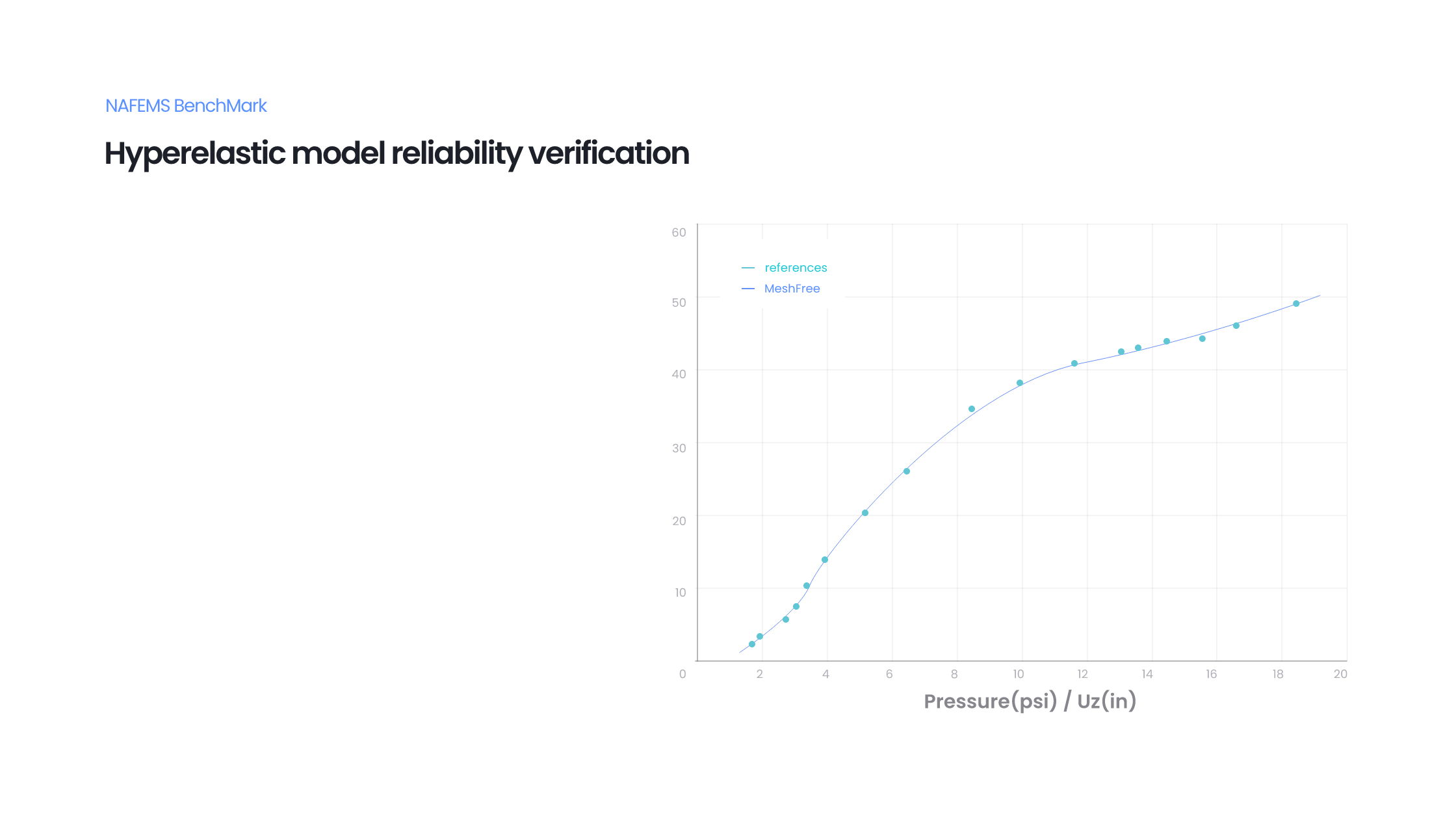

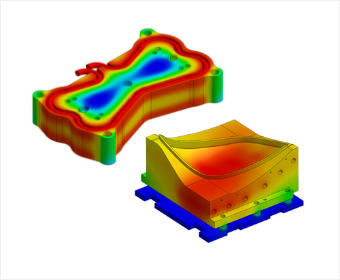

Performance analysis of rubber materials

Performance analysis of rubber materials

Switch Module Natural Frequency Analysis

Switch Module Natural Frequency Analysis

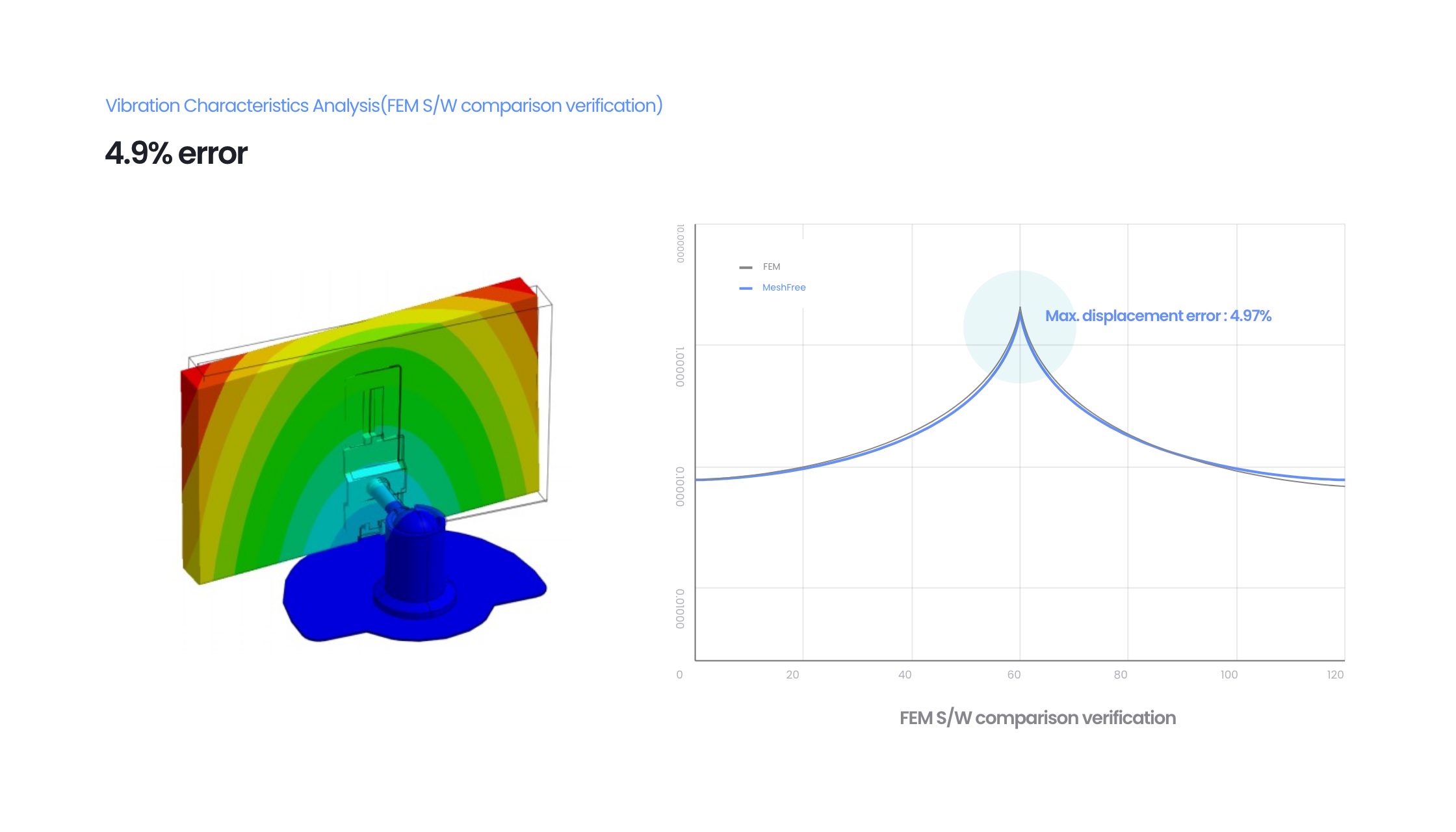

Gearbox Dynamic Characteristics Analysis

Gearbox Dynamic Characteristics Analysis

Laser Inspection Machine Operational Stability Evaluation

Laser Inspection Machine Operational Stability Evaluation

Medical Device Support Impact Simulation

Medical Device Support Impact Simulation

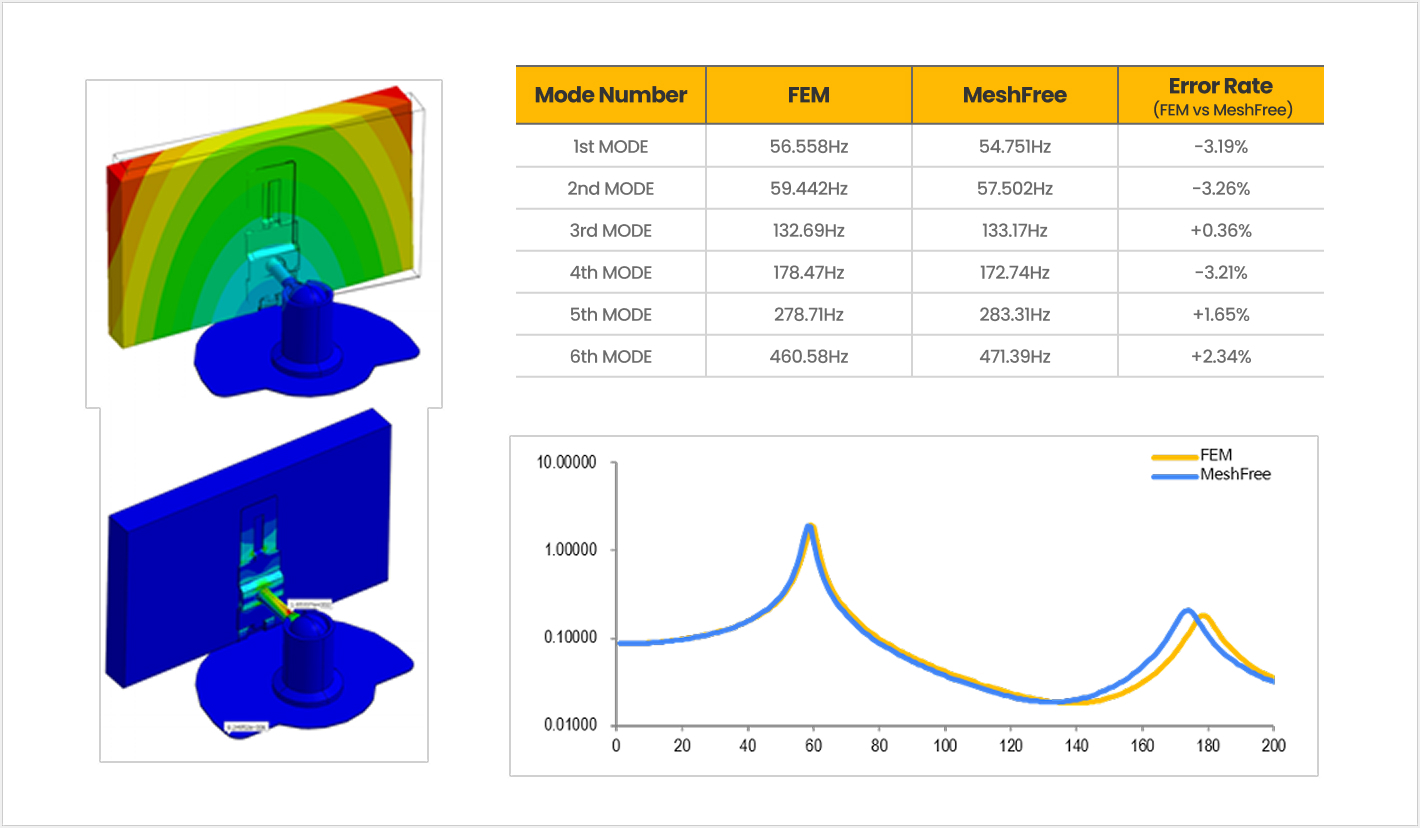

Automotive Monitor Dynamic Characteristics Analysis

Automotive Monitor Dynamic Characteristics Analysis

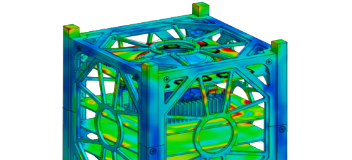

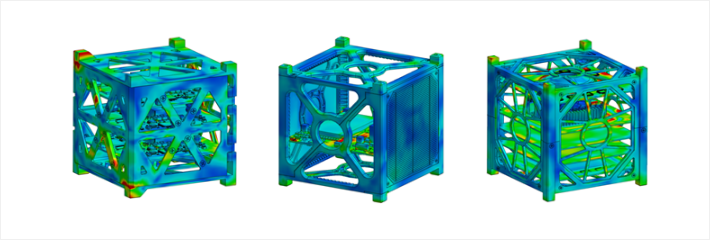

CubeSat Random Vibration Analysis

CubeSat Random Vibration Analysis

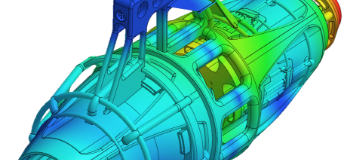

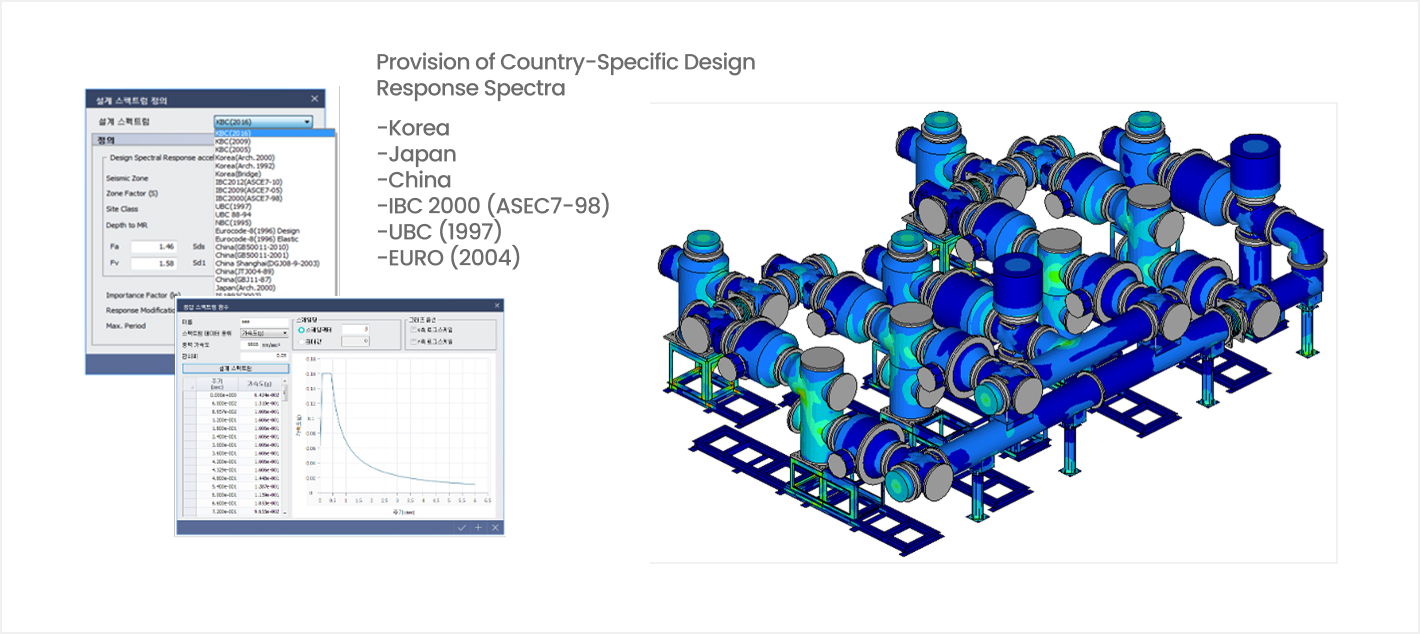

Gas Insulated Switchgear (GIS) Seismic Verification

Gas Insulated Switchgear (GIS) Seismic Verification

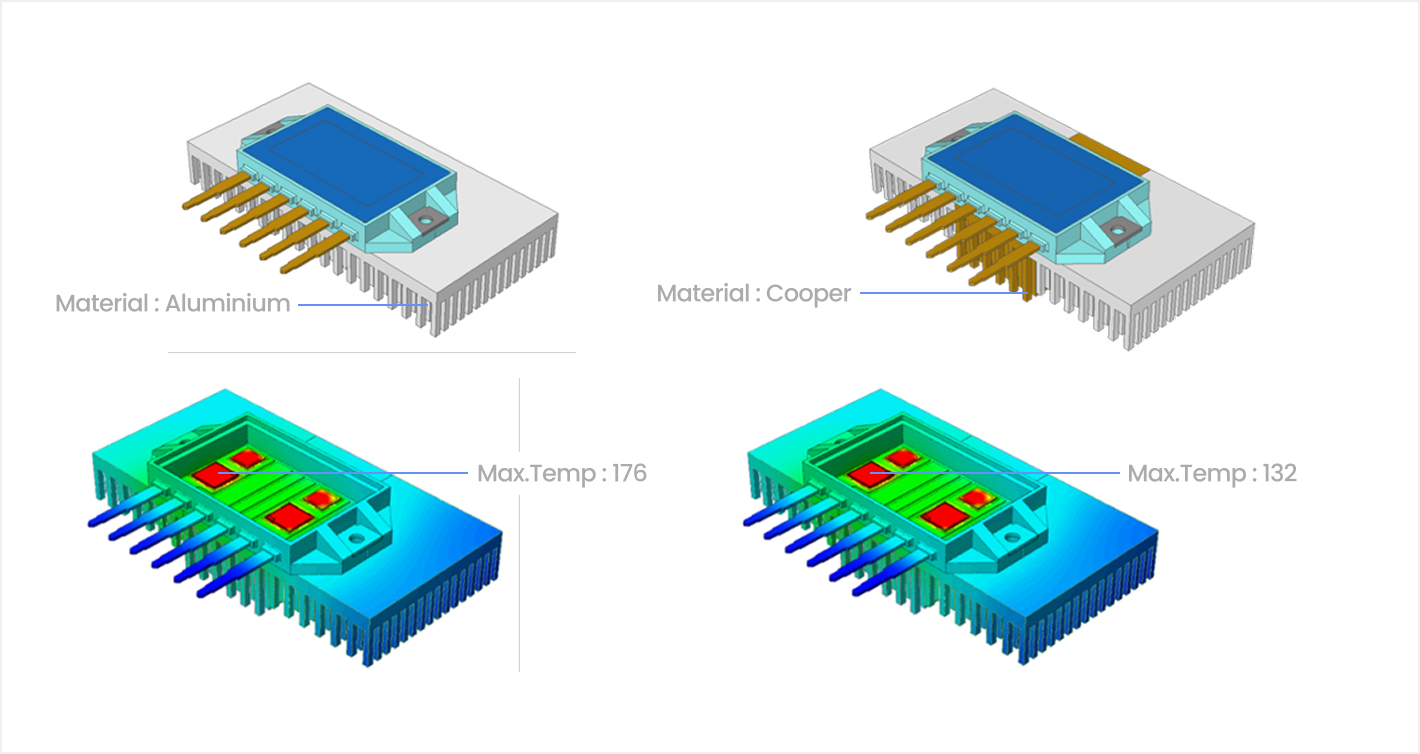

MOSFET Heat Sink Cooling Performance Improvement

MOSFET Heat Sink Cooling Performance Improvement

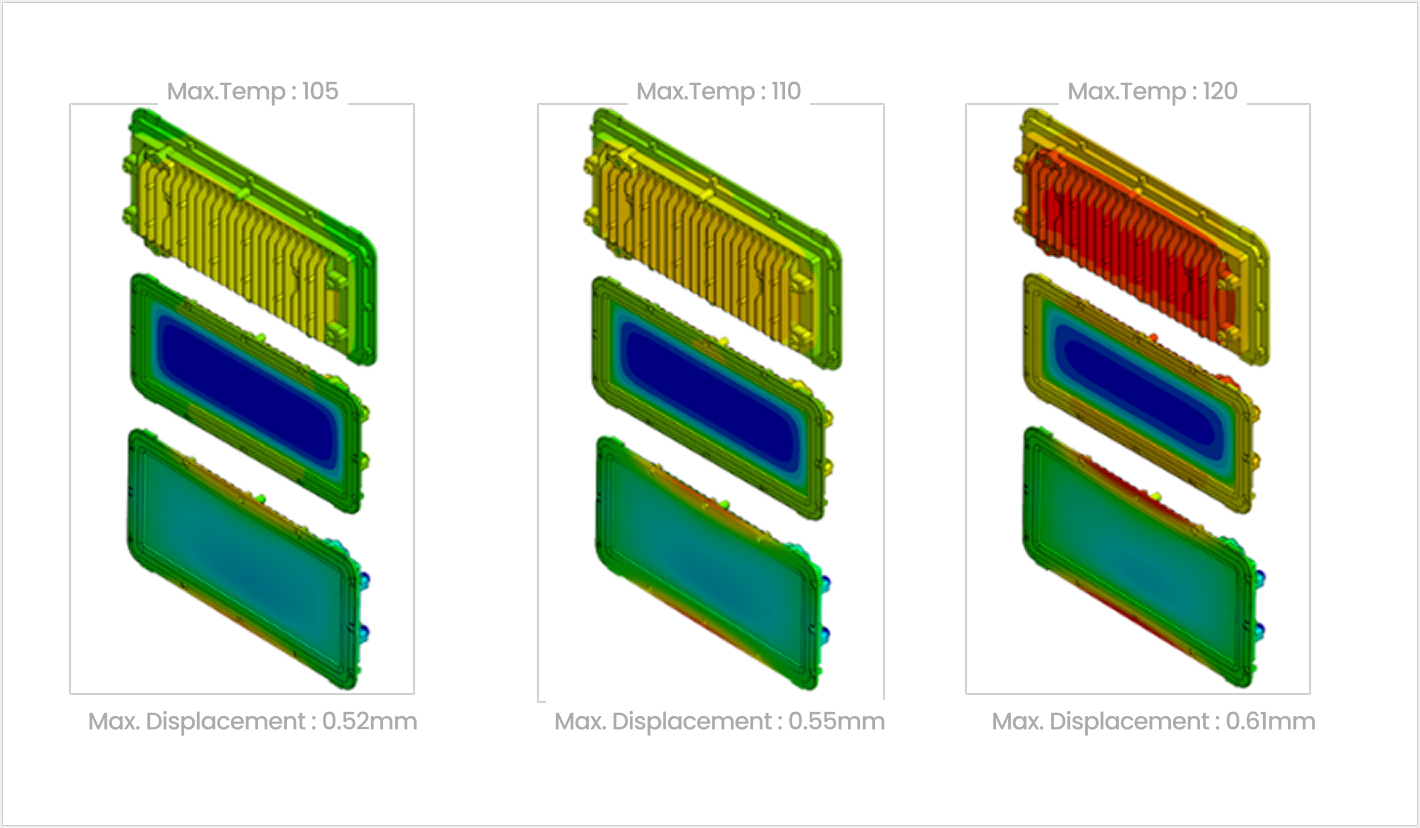

Temperature Evaluation due to LED Chip Heat Generation

Temperature Evaluation due to LED Chip Heat Generation

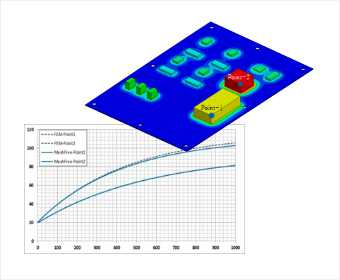

Chipboard Transient Heat Transfer Analysis Comparison and Verification

Chipboard Transient Heat Transfer Analysis Comparison and Verification

Sheath Heater and Housing Jig Transient Heat Transfer Analysis

Sheath Heater and Housing Jig Transient Heat Transfer Analysis

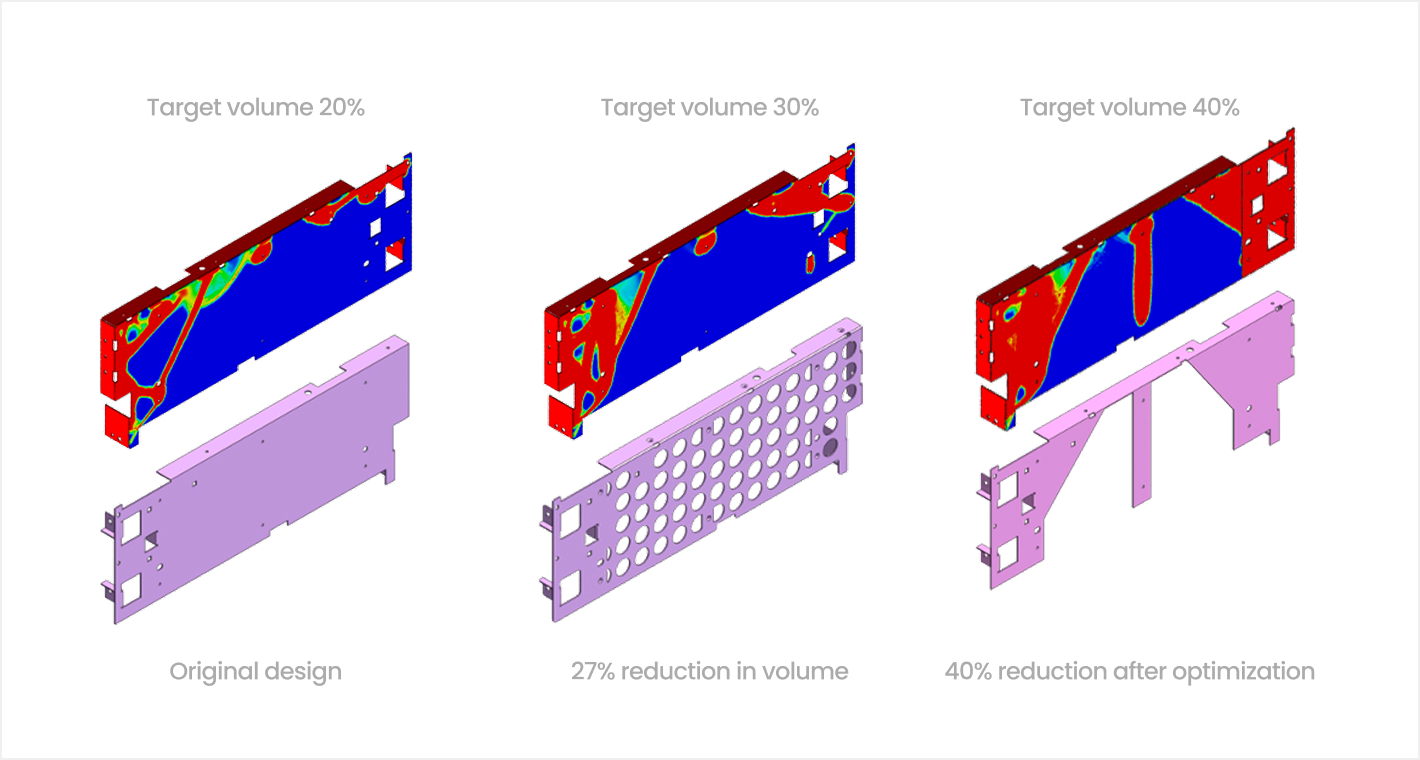

Optimal Design of Bracket Shape for Stiffness Retention

Optimal Design of Bracket Shape for Stiffness Retention

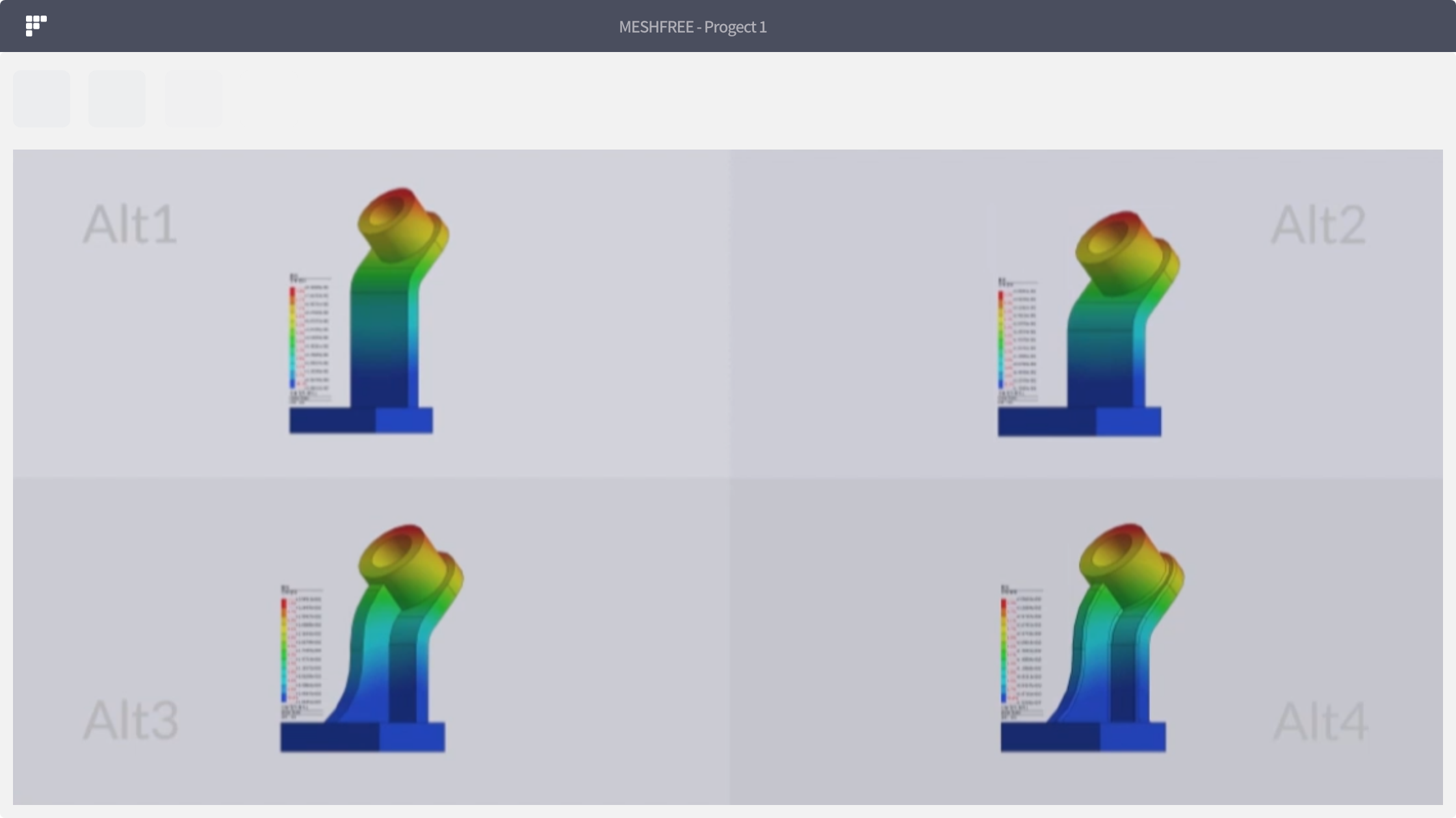

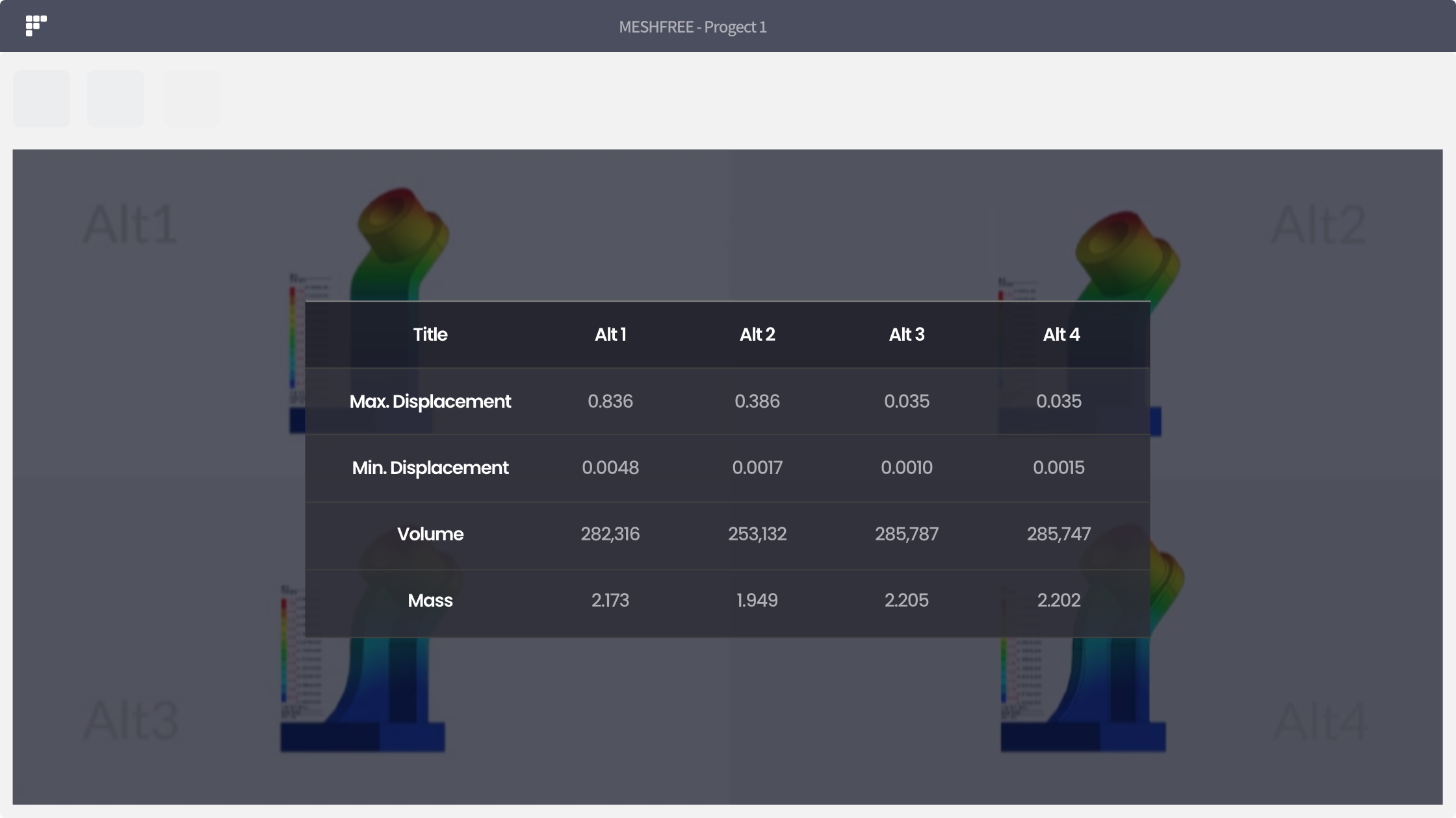

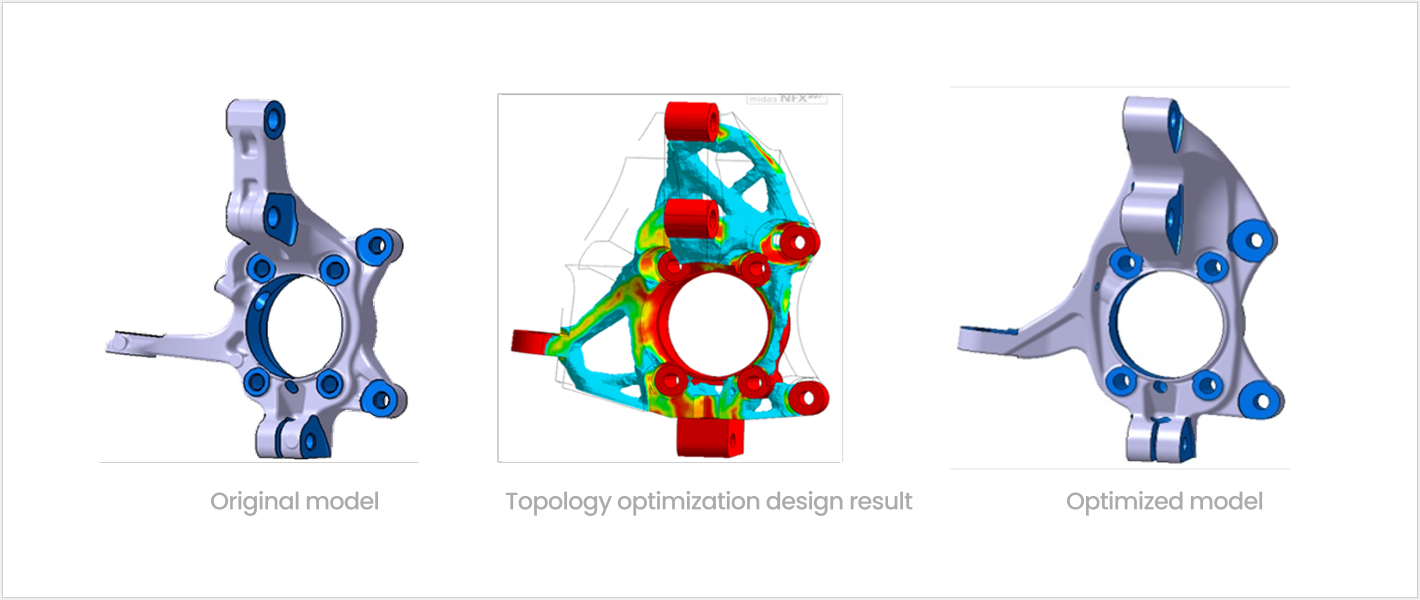

Derivation of Optimal Shape for Automotive Knuckle

Derivation of Optimal Shape for Automotive Knuckle